Design department

ATEX

PREVENTION AGAINST EXPLOSION RISKS

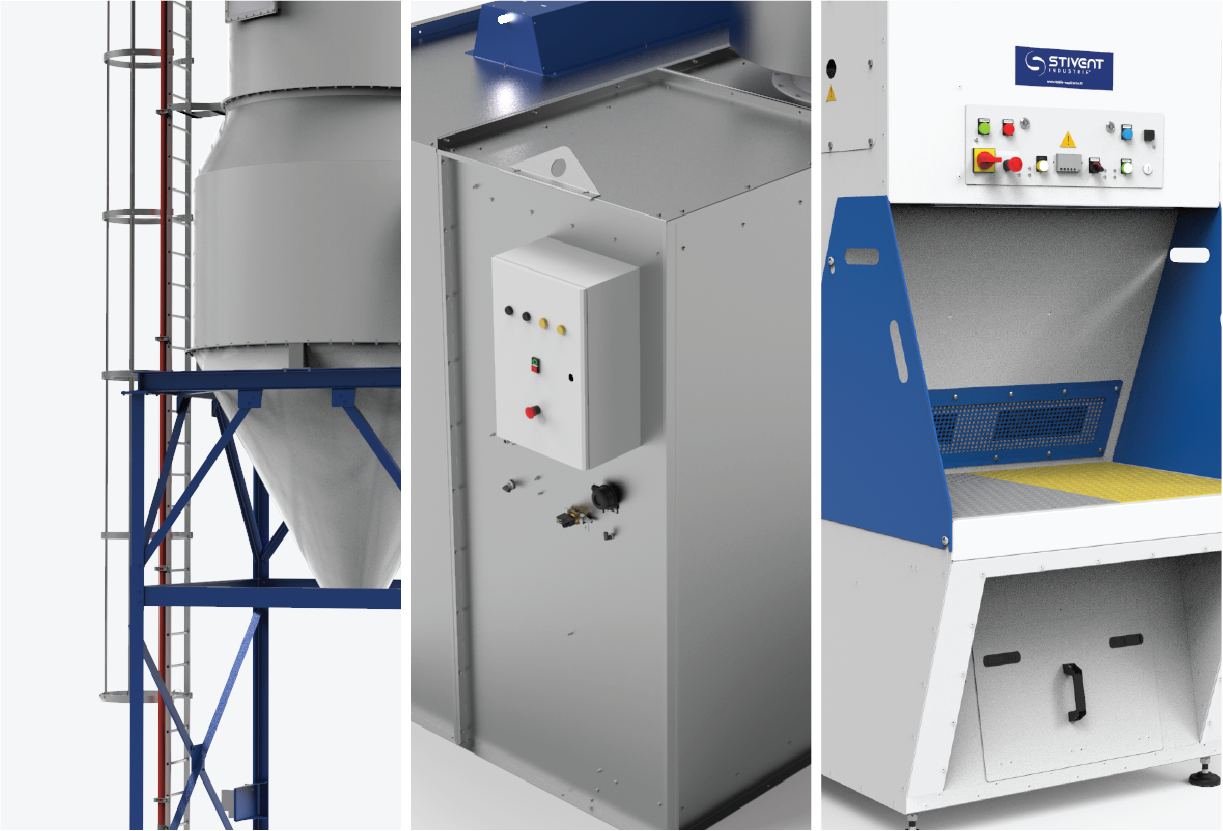

STIVENT INDUSTRIE® specialises in the design, manufacture and installation of equipment for the treatment and purification of industrial air. In their manufacturing process, our clients are confronted with the explosive nature of the pollutants generated by their activities.

Dust, powders, gases, liquids and other waste emitted can cause accidents such as explosions, fires and injuries. In 64% of cases, this also causes operating losses.

To protect themselves from the explosion risks associated with the equipment, and in accordance with the ATEX directive 2014/34/EU, manufacturers are obliged to use ATEX certified equipment. The equipment must comply with the technical prescriptions linked to the types of zone.

ATEX standards are regulated by European directives transposed in the form of a law applicable in each country: they are compulsory (France _ articles R. 4216-31 and R. 4227-42 to R. 4227-54 of the Labour Code).

They also provide for the marking of equipment using a regulatory pictogram. It identifies areas of the workplace where explosive atmospheres can be formed.

"Explosive Atmosphere or ATEX (ATmosphère EXplosive): the mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapours, mists or dust, in which, after ignition, combustion spreads to the whole unburned mixture".

Source: European Directive 2014/34/EU of February 26, 2014.

CLASSIFICATION OF ATEX ZONES

The classification of zones in which an ATEX is likely to form is the responsibility of the facility manager. They are defined according to the type and the probability of encountering such an atmosphere.

|

LIKELIHOOD OF ATEX |

HIGH More than 1000 hours/year Explosive atmosphere present permanently or for long periods in normal operation |

MEDIUM AND LOW Between 10 and 1000 h/year Explosive atmosphere occasionally occurs during normal operation |

VERY LOW Between 1 and 10 hours/year Explosive atmosphere accidentally present, in the event of malfunction or short-term |

|---|---|---|---|

|

GAS/VAPOUR AREA |

0 | 1 | 2 |

|

DUST ZONE |

20 | 21 | 22 |

However, by choosing STIVENT INDUSTRIE® equipment to assist your manufacturing processes, you are also choosing a turnkey solution.

Currently more than 25% of STIVENT INDUSTRIE® staff is ATEX level 2 certified. Whether it is the design office, maintenance, salespeople, etc., all have acquired the level of ATEX certification known as “EXPERTS”. This certification allows us to competently handle all design, production, installation and maintenance tasks for industrial air filtration devices in explosive atmospheres.

Thus, STIVENT INDUSTRIE® is able to define with you the appropriate protection and prevention measures taking into account your constraints and the work environment.

Need support? Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find an efficient solution.