Company

Industrial filtration

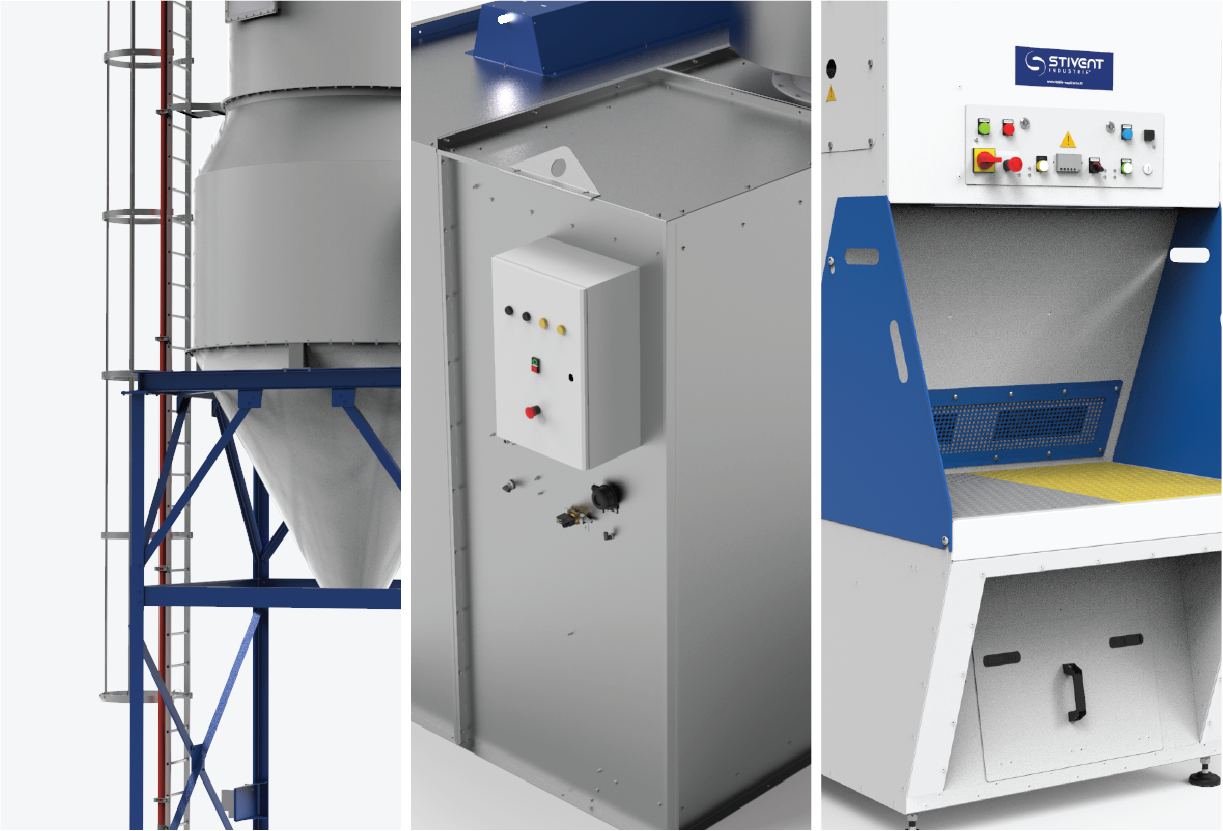

Fine particles, cutting fluids, oil mists... your industry generates this type of element in its manufacturing process. STIVENT INDUSTRIE® studies, designs, manufactures, installs and monitors tailor-made solutions for the treatment of exhaust air.

A reliable and efficient industrial filtration installation meets the minimum prevention requirements to which STIVENT INDUSTRIE® practically subscribes.

The following 4 steps are systematically screened:

- Appropriate and optimised capture device

- Adapted transport network

- Air treatment before discharge

- Control of filtration installations

The polluted air capture device offered by STIVENT INDUSTRIE® will be subject to a careful analysis of the workstation to be equipped, itself integrated into an industrial process: grinding, sanding, machining, mechanical rectification, etc., and the nature of the pollutants to be filtered (vapours, fumes, aerosols, fine particles, oil mists, etc.).

The specifications of the industry (the client) will inform of the various constraints to be taken into account. For example: if the capture is fixed or mobile. It will give the indications of location, positioning and possible sizing of the filtration device to be considered which are obviously taken into account from this project analysis step.

Next comes the aeraulic data for which the calculations of capture speed, ventilation, air flow, make-up air supply, etc. are methodically tested, proven and validated to guarantee all the expected performance.

The captured air transport network must be adapted to all the aeraulic data defined in the previous step, but must also take into account the choice of network and the type of network optimised within the industry (herringbone network, with additional air inlet, with variable flow…).

The treatment of the captured air allows separating or filtering air and pollutants (dust, waste in a cutting fluid, oil residue, etc.) via a filtering medium appropriate to the source of the flows to be treated. Filtration allows the reintroduction of certain particles into the industrial process if necessary, which then generates savings via recycling - example: Gold, Platinum, Rhodium dust, etc., is not thrown away.

The control of the filtration installations is compulsory, since installation, then periodically; because intrinsic modifications of the particles to be filtered, changes of filters, require regular recalibration (annual and/or semi-annual) of the air filtration devices to guarantee the required level of performance.

EXPLOSIVE ATMOSPHERE!

More than 25% of STIVENT INDUSTRIE® staff is ATEX level 2 certified. From the design office to the maintenance, including the engineering office, the quality office and even the sales staff - all have acquired the ATEX certification level known as “EXPERTS”, allowing them to deal with skills for all design, production, installation and maintenance tasks for industrial air filtration devices in explosive atmospheres.

All our industrial air filtration systems are designed to meet a double objective: improving the air quality at work and the working conditions of operators according to the recommendations of INRS, CARSAT and that in the compliance with ATEX standards.