Company

Industrial extraction

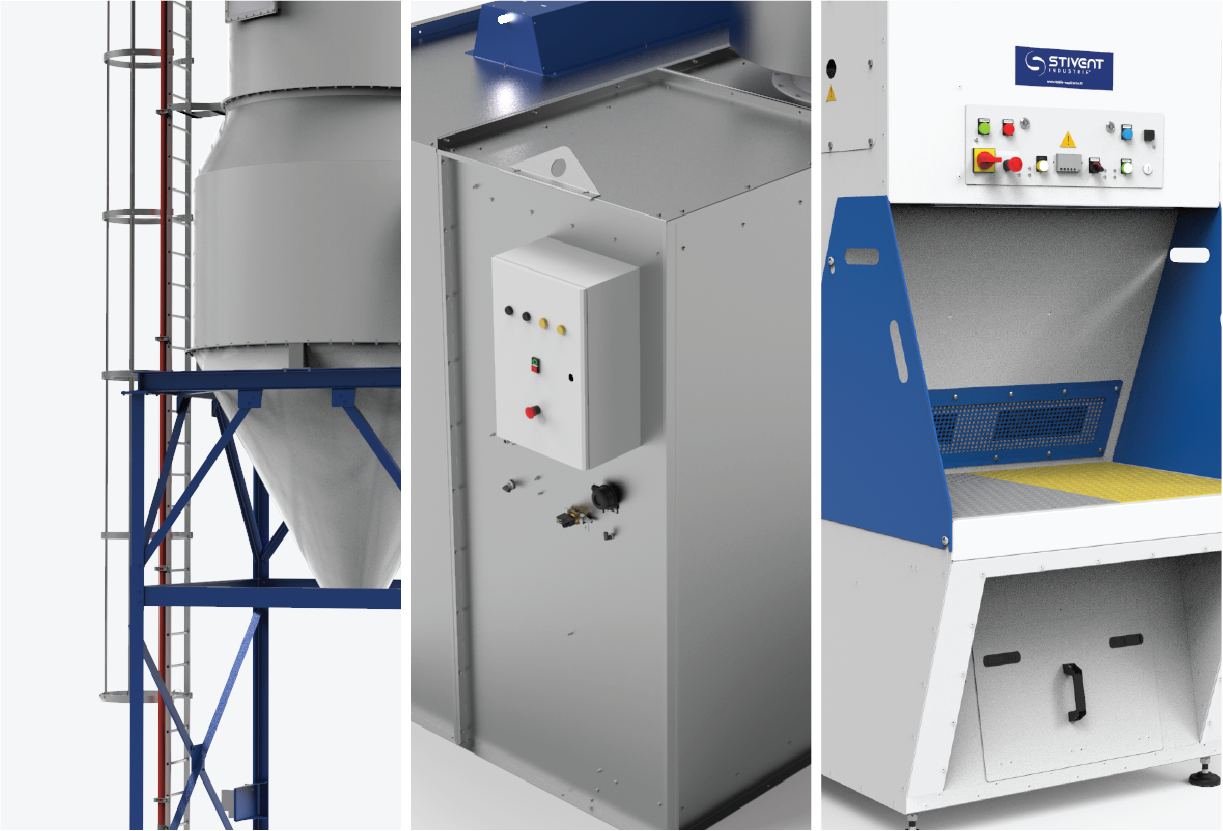

Hospitals, craft, industries of all sectors: sawmill, chemistry, aeronautics, automotive, food industry... All these sectors of activity generate dusts, vapours, fumes, gases, etc., which it is imperative to control and eliminate. STIVENT INDUSTRIE® studies, designs and manufactures in France industrial suction systems.

Dust, material residues, volatile particles, whatever their nature, affect production processes at all levels. And at STIVENT INDUSTRIE® more than ever, everything is thought and done to fulfil at least a double objective:

- improving air quality

- improving the working conditions of operators

IMPROVING AIR QUALITY: THE DUAL CHALLENGE

Companies in all sectors take care to exclude as much as possible the sources of pollutants (vapours, fumes, gases, aerosols, dust, etc.) which would favour pathologies affecting the respiratory system or the skin. It is common today a greater recourse to neutral products (water-based paint, vegetable ink, “clean” oils…) but to perfect these approaches, the provision of suction equipment is imposed.

The installation of a dust, fume, or vapour suction device serves a dual purpose. Of course, improving air quality to secure the health of personnel working on machine tools and at the same time prevent technical risks such as fire, explosion, etc.

By capturing pollutants as close as possible to the source of emission, productivity gains are quickly observed by production managers. In fact, machines sensitive to meticulous adjustments are no longer impacted by dust.

The quality of industrial air is therefore part of a global quality approach and takes its place in industrial processes.

IMPROVING AIR QUALITY: THE MEANS - THE METHOD

Because there are as many suction devices as there are sources of pollutant emissions, it is not easy to find yourself alone and make the right choice.

This is why STIVENT INDUSTRIE® always studies the optimal solution from the extraction problem to be solved. STIVENT INDUSTRIE® will have to identify if it is a question of treating the air according to sanding, grinding, polishing, rectification, deburring applications, etc., or even painting, cleaning, degreasing, stripping, or mixing, dosing, weighing operations, etc.

All environmental requirements and configuration requirements for workstations, all technical constraints related to the nature of industrial activity are then scrupulously studied (nature of pollutants: flour, wood, metal; explosive environment, etc.). Taking these criteria into account as a whole STIVENT INDUSTRIE® can validate specifications with its client.

All the steps necessary for the proper progress of an installation will be approved and comply with the study, development, manufacturing, installation and control phases, and be in strict compliance with European regulations.

It is essential that the suction system is perfectly effective in protecting the operator at his/her workstation and ensuring the quality of the surrounding air.

- Will your choice be directed towards a compact and mobile downdraft table?

- Is this a backsplash table that is essential in your case?

- The suction device must absolutely be ATEX certified.

- Autonomy and profitability are also criteria to take into account in your choices…

All our standard solutions are scalable and customisable according to the extraction problem to be solved in your industrial production universe. Can't find the information that answers your questions? Contact us for information or a challenge to be addressed!