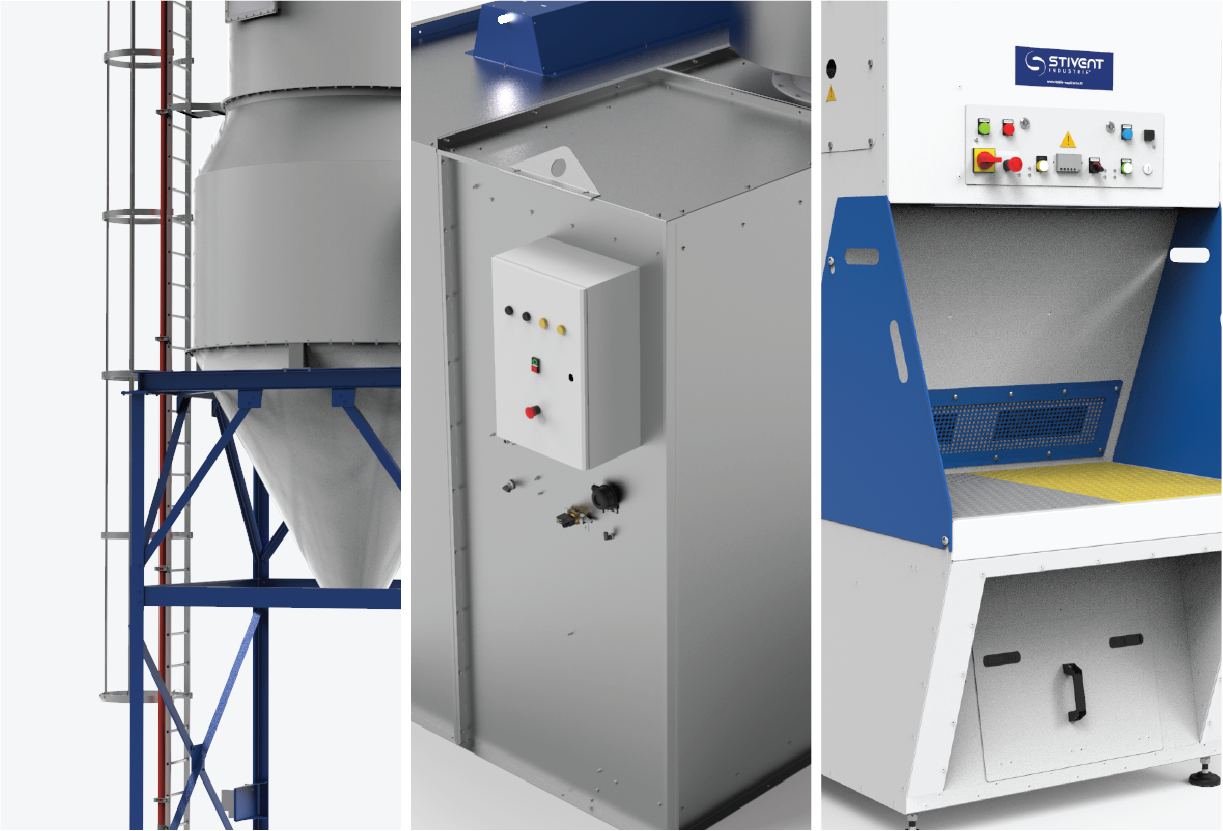

Products

Piping

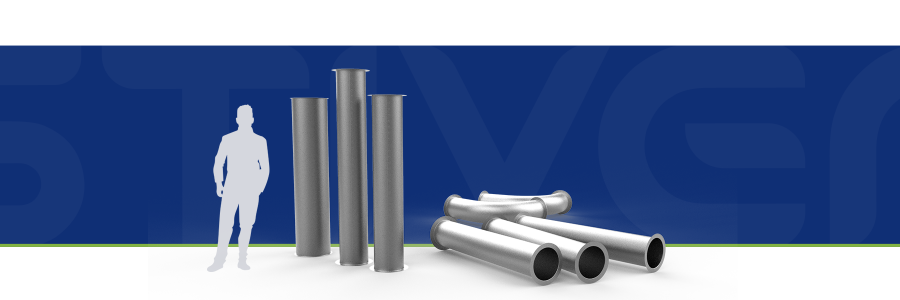

PIPING AND ITS COMPONENTS FOR SUCTION OF INDUSTRIAL DUST

An essential element of industrial suction and filtration systems, piping is an important parameter for the proper operation of an aeraulic network over time.

The choice of the type of piping to be used is made according to:

- the application

- the nature and quality of the air conveyed

- the nature, quantity, concentration and type of dust transported

- air flow speed

- the location

Manufacturer since 1962, the piping ranges offered by STIVENT INDUSTRIE® apply to all industrial sectors including food industry.

Our production workshop, in direct connection with the design office, allows us to produce specific piping elements or parts, adaptable to original equipment other than STIVENT INDUSTRIE®. Thanks to our fleet of machines including laser and plasma cutting, bending machine tools, rolling balancing, we are able to manufacture any piping element and component necessary for industrial suction, filtration, and dust extraction.

Our piping ranges are smooth and circular. They include, among other things, straight pipes, elbow elements, swivel fittings, lip pipes, Y-connections also called "culotte", flexible tubing, etc. We are also one of the last French manufacturers of pipe hose clamps .

RANGE FEATURES

To adapt to your needs, our range of piping are available in many diameters outside the standard from the diameter 80 mm. Thus, we are able to adjust our networks in order to optimise material transport speeds and achieve energy savings while guaranteeing the recommendations of INRS

The constructions can be made of galvanised steel (standard) or stainless steel. Optionally it is possible to paint the galvanisation for an effect according to your aesthetic desires.

All our products are guaranteed for 5 years excluding wear and tear related to abrasion.

Good to know

For any order placed before 11 a.m., we can urgently send you any single piece of piping. Thanks to this service +, we are able to troubleshoot our clients in the event of a shortage on a site, and thus avoid blocking an assembly team for a single part.

Need support or additional information? Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find an efficient solution.