Products

Cyclone

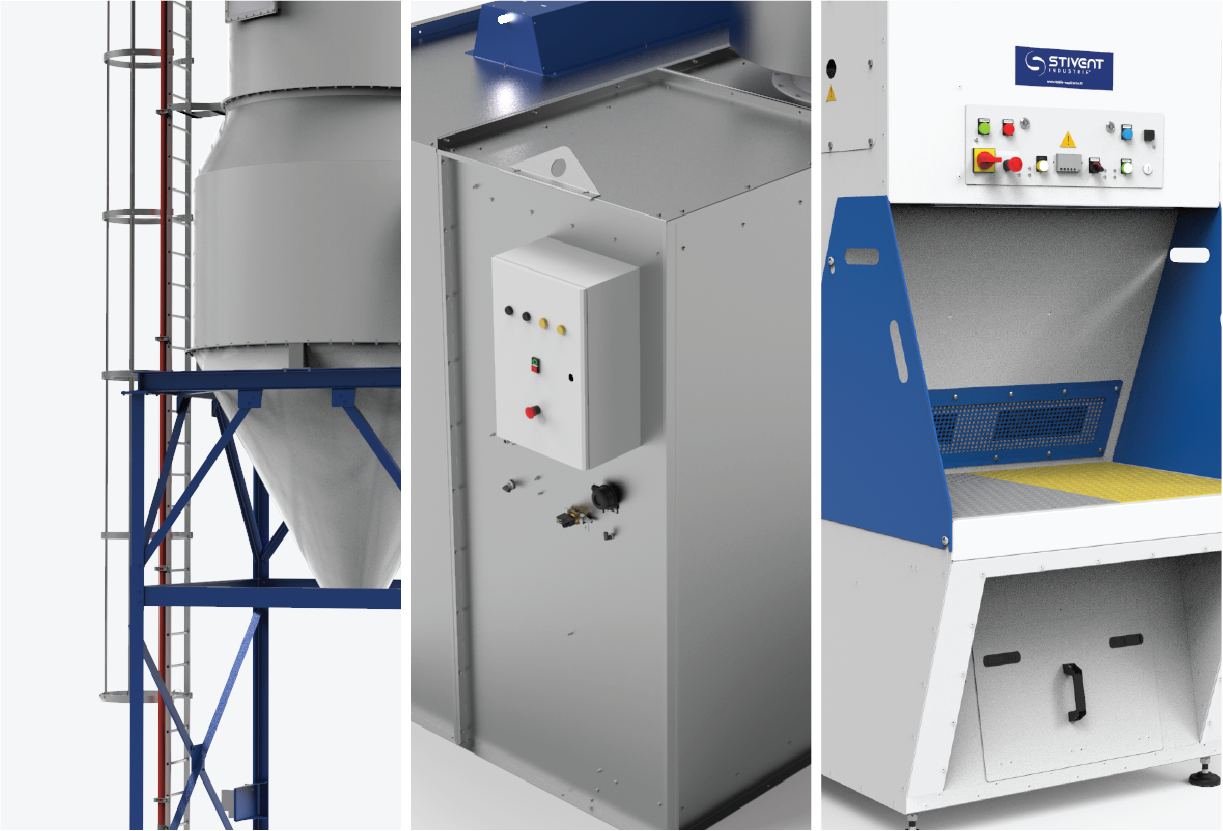

CYCLONE FOR THE TREATMENT OF DUST AND CHIPS

AUTONOMOUS - ECONOMICAL - RESISTANT - SECURE - RELIABLE - EFFECTIVE

STIVENT INDUSTRIE® designs and develops cyclones to improve working conditions in dusty areas.

As a pre-separation element for industrial dust and wood, cyclones are often used to rid the incoming air of dust and/or chips with which it can be charged. They are a useful complement in a filtration network because they allow a pre-separation of air and material upstream of the filter.

In the event of explosive dust, these cyclones comply with ATEX safety.

In the event of explosive dust, these cyclones comply with ATEX safety.

Effective, no dust escapes it with its flow rate capacity from 1,500 to 30,000 m3/h.

Efficient, capable of performance up to 99% for dense and/or bulky dust, the cyclone is the most economical solution for capturing and treating exhaust air.

Economical for the planet and for industries, less consumable, less spare parts, low maintenance cost and possibility of discharging air in the workshop.

Adaptability, with 3 different ranges, cyclones cover most needs. Options are also available to further improve their use.

Convenience, they are designed as standard with inspection hatch and internal setting(s).

Reliability, solution proven with industrial grade components, a product designed to last.

Applications: Sawmills, heavy dust, operations creating chips, sandblasting….

Options

- Pressure or vacuum operation

- Stainless steel reinforcement

- Output transformation

- Adaptation for tub, big bag or bucket

STIVENT INDUSTRIE® offers a wide range of cyclones tested in digital simulation and of course long-time proven in practical use by our clients.

All of our products are customisable and/or scalable according to your needs and technical constraints. Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find a solution.

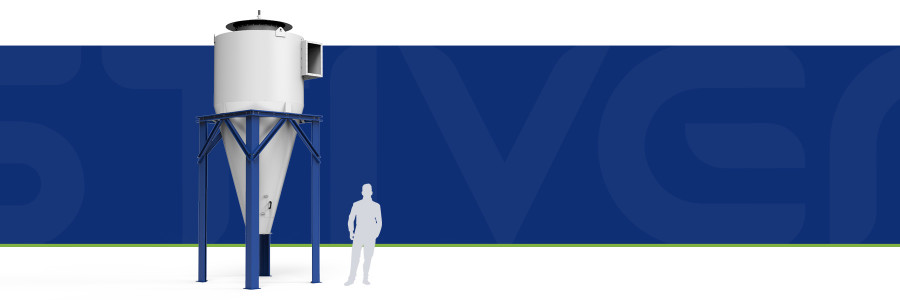

OPERATION

Cyclones use centrifugal force and the pressure difference to separate particles from the air to be cleaned. The particle size, density and rotational speed of the particles affect efficiency.

Exhaust air comes in through the tangential inlet. The airborne dust is then drawn against the walls under the effects of a cyclonic movement. By gravity, the largest particles fall into the hopper to be possibly recovered and treated. The finest dust (on the order of 5 to 10 µ) is captured by filter elements. The purified air is subsequently blown into the factory or released into the atmosphere.

Used before a cartridge filter or a bag filter to preserve the filtering medium or mounted alone in sawmills or other, it has a reliable and constant performance over time.

In pictures and videos

| Download files |

|---|

| Cyclone - Download data sheet and options |